How does a centrifugal pump work?

How does a centrifugal pump work?

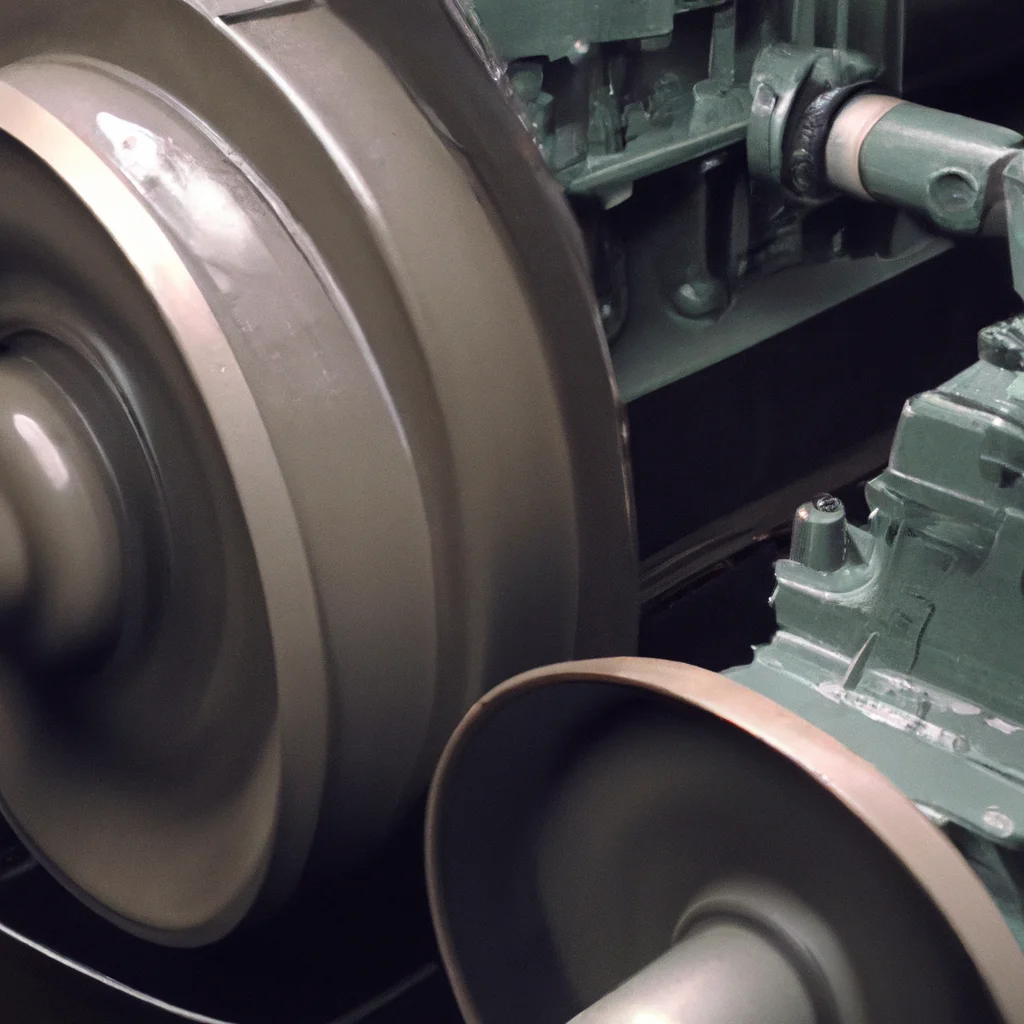

A centrifugal pump is a mechanical device that converts mechanical energy into hydraulic energy. It does this by utilizing the centrifugal force generated by a rotating impeller to move fluids. Centrifugal pumps are commonly used in various applications, such as water supply systems, chemical processing, irrigation, and many others. In this article, we will discuss the working principle, components, design, efficiency, maintenance, troubleshooting, and applications of a centrifugal pump.

Pump Working Principle

A centrifugal pump works on the principle of centrifugal force. The mechanical energy from the motor is transferred to the impeller through the shaft. The impeller rotates at a high speed, creating a centrifugal force that moves the fluid towards the outlet of the pump. As the fluid flows through the impeller, it gains kinetic energy, which is converted into potential energy as the fluid is discharged through the outlet.

Pump Operation

Centrifugal pumps operate by creating a low-pressure zone near the impeller’s center and a high-pressure zone near the outer edge. This pressure difference generates a force that moves the fluid towards the outlet. The pump’s suction line is connected to the fluid source, and the discharge line is connected to the system that requires the fluid. The pump operation is affected by several factors, such as the impeller diameter, rotational speed, and fluid viscosity.

Pump Components

A centrifugal pump consists of several components, such as the impeller, casing, shaft, bearings, and seals. The impeller is the rotating component that generates the centrifugal force. The casing is the stationary component that houses the impeller and directs the fluid towards the outlet. The shaft connects the impeller to the motor and transmits the mechanical energy. The bearings support the shaft and reduce friction. The seals prevent the fluid from leaking from the pump.

Pump Design

Centrifugal pumps are designed to meet various requirements, such as flow rate, head, and efficiency. The pump design depends on the application and the fluid properties, such as viscosity, temperature, and corrosiveness. The impeller design plays a crucial role in the pump performance, as it affects the flow rate, head, and efficiency. The casing design also affects the pump performance, as it determines the fluid flow path and the pressure distribution.

Pump Efficiency

Pump efficiency is a measure of how well the pump converts the mechanical energy into hydraulic energy. The pump efficiency depends on several factors, such as the impeller design, casing design, rotational speed, and fluid properties. The pump efficiency can be improved by selecting the appropriate impeller and casing design, operating the pump at the optimal speed, and maintaining the pump components.

Pump Maintenance

Pump maintenance is essential to ensure the pump operates optimally and reliably. The maintenance activities include inspecting the pump components, such as the impeller, casing, shaft, bearings, and seals, and replacing any worn or damaged parts. The maintenance also includes monitoring the pump performance, such as the flow rate, head, and efficiency, and adjusting the operational parameters, such as the rotational speed and fluid properties, to optimize the pump performance.

Pump Troubleshooting

Pump troubleshooting is necessary to identify and resolve any issues that may arise during the pump operation. The common pump issues include low flow rate, low head, low efficiency, vibration, noise, and leakage. The troubleshooting activities include inspecting the pump components, such as the impeller, casing, shaft, bearings, and seals, and identifying any wear or damage. The troubleshooting also includes adjusting the operational parameters, such as the rotational speed and fluid properties, to optimize the pump performance.

Pump Applications

Centrifugal pumps are widely used in various applications, such as water supply systems, chemical processing, irrigation, HVAC, and many others. The pump selection depends on the application requirements, such as flow rate, head, and fluid properties. The pump materials also depend on the fluid properties, such as viscosity, temperature, and corrosiveness.

Conclusion

In conclusion, a centrifugal pump is a mechanical device that converts mechanical energy into hydraulic energy. It works on the principle of centrifugal force and consists of several components, such as the impeller, casing, shaft, bearings, and seals. The pump design, efficiency, maintenance, and troubleshooting depend on several factors, such as the impeller design, casing design, rotational speed, and fluid properties. Centrifugal pumps are widely used in various applications and play a crucial role in many industrial processes.

Recent Posts

How do I create an engaging and informative online quiz or assessment?

Creating an engaging and informative online quiz or assessment can be a powerful tool for… Read More

What are the most effective methods for managing and reducing work-related stress in the hospitality industry?

Work-related stress is a common issue in the hospitality industry, where employees often face long… Read More

How can I improve my assertiveness and communication skills in a leadership position?

In a leadership position, assertiveness and effective communication skills are crucial for success. Being able… Read More

What are the key elements of a successful employee recognition and rewards program?

Employee recognition and rewards programs play a crucial role in motivating and engaging employees, as… Read More

How do I effectively manage and respond to customer feedback and reviews?

Customer feedback and online reviews play a crucial role in shaping a company's reputation and… Read More

What are the best strategies for effective time management as a stay-at-home parent?

Effective time management is crucial for stay-at-home parents who juggle multiple responsibilities on a daily… Read More