Fractional distillation is a process used to separate two or more liquids with different boiling points. It is a commonly used method in industries such as oil refining, chemical manufacturing, and beverage production. The process involves heating a mixture of liquids to vaporize and then condense them separately based on their boiling points. In this article, we will discuss how the process of fractional distillation works, the apparatus used, and the different steps involved.

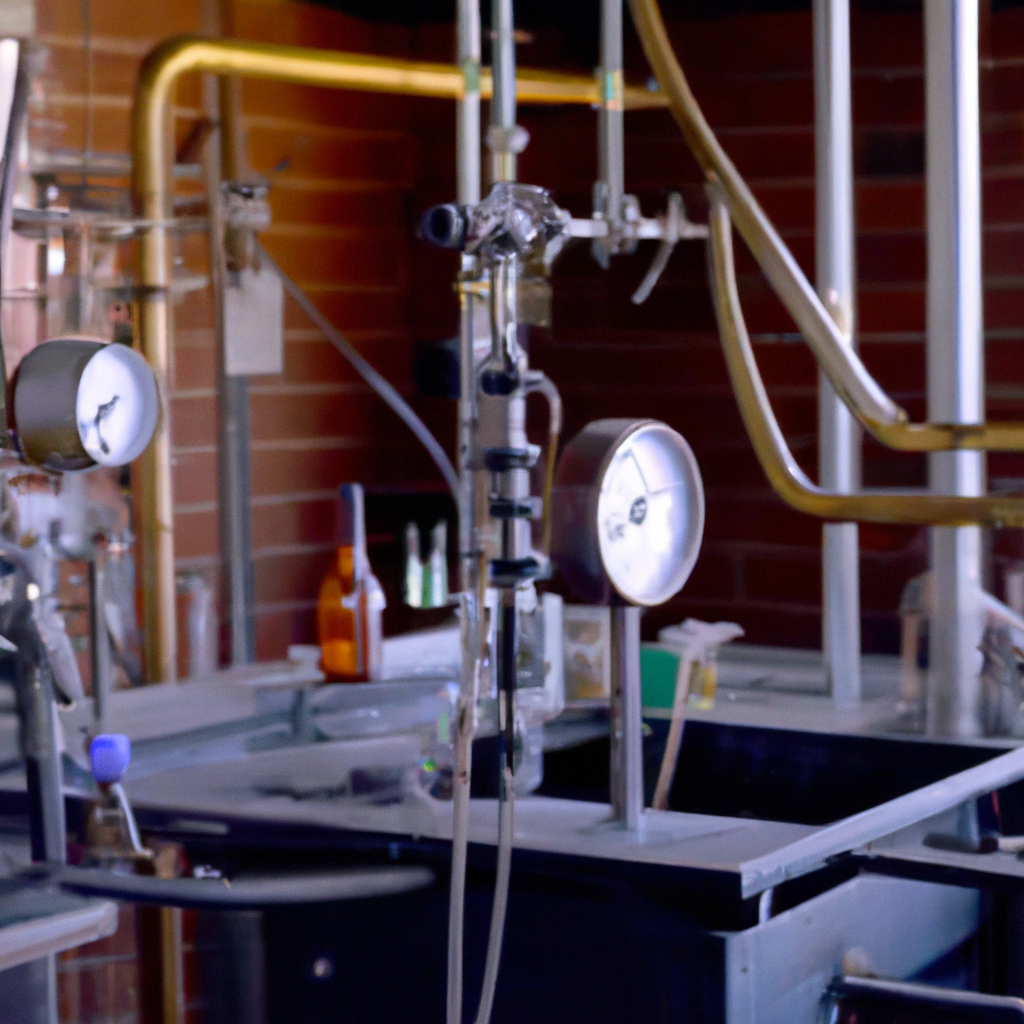

Apparatus used in Fractional Distillation

The fractional distillation apparatus consists of a distillation column that is packed with glass beads or metal pieces to increase the surface area for vaporization and condensation. The column is equipped with a temperature gradient, which allows the separation of liquids based on their boiling points. The column also has a condenser, which cools the vaporized liquids back into liquids.

Distillation Process Steps

The distillation process starts with the heating of the mixture of liquids in a flask. The heat source is applied to the bottom of the flask, which causes the liquids to vaporize. The vaporized liquid then rises up the column, where it comes in contact with the packing material.

As the vaporized liquid rises up the column, it starts to cool down and condense back into a liquid. The packing material provides a large surface area for the vaporized liquid to come in contact with, which allows for efficient condensation. The liquids with higher boiling points will condense at the lower end of the column, while the liquids with lower boiling points will condense at the higher end of the column.

The condensed liquids are collected in separate receivers at the bottom of the column. The temperature of the column is gradually increased, and the process is repeated until all the liquids are collected in separate receivers.

Factors that Affect the Fractional Distillation Process

The boiling point of the liquids is the primary factor that affects the fractional distillation process. The liquids with higher boiling points will condense at the lower end of the column, while the liquids with lower boiling points will condense at the higher end of the column.

Another factor that affects the fractional distillation process is the composition of the mixture of liquids. The composition of the mixture will determine the temperature at which the liquids will vaporize and the rate at which they will condense.

Crude Oil Distillation

One of the most common applications of fractional distillation is the refining of crude oil. Crude oil is a complex mixture of hydrocarbons with different boiling points. The refining process involves heating the crude oil to vaporize the different hydrocarbons, which are then separated based on their boiling points.

The distillation process starts with the heating of the crude oil in a distillation column. As the crude oil heats up, the different hydrocarbons vaporize and rise up the column. The hydrocarbons with higher boiling points will condense at the lower end of the column, while the hydrocarbons with lower boiling points will condense at the higher end of the column.

The different hydrocarbons are collected in separate receivers at the bottom of the column. The collected hydrocarbons are then further processed to produce different products such as gasoline, diesel, and jet fuel.

Conclusion

Fractional distillation is a process used to separate two or more liquids with different boiling points. The process involves heating a mixture of liquids to vaporize and then condense them separately based on their boiling points. The fractional distillation apparatus consists of a distillation column that is packed with glass beads or metal pieces to increase the surface area for vaporization and condensation. The column is equipped with a temperature gradient, which allows the separation of liquids based on their boiling points. The boiling point of the liquids and the composition of the mixture are the primary factors that affect the fractional distillation process. The process is commonly used in industries such as oil refining, chemical manufacturing, and beverage production.