Artificial Intelligence (AI) has revolutionized many industries, and predictive maintenance is one of them. Predictive maintenance is a proactive approach to maintenance, where potential equipment failures are identified before they occur. This approach is highly effective in reducing downtime, increasing equipment lifespan, and minimizing maintenance costs. In this article, we will explore how AI is used in predictive maintenance and its impact on the industry.

AI-Powered Predictive Maintenance

The traditional approach to maintenance is reactive, where equipment is fixed after it fails. However, this approach is not effective in preventing downtime, as it results in unexpected equipment failures, which can lead to unplanned downtime, lost production, and increased maintenance costs. Predictive maintenance, on the other hand, allows maintenance personnel to identify potential equipment failures before they occur, reducing downtime, maintenance costs, and increasing equipment lifespan.

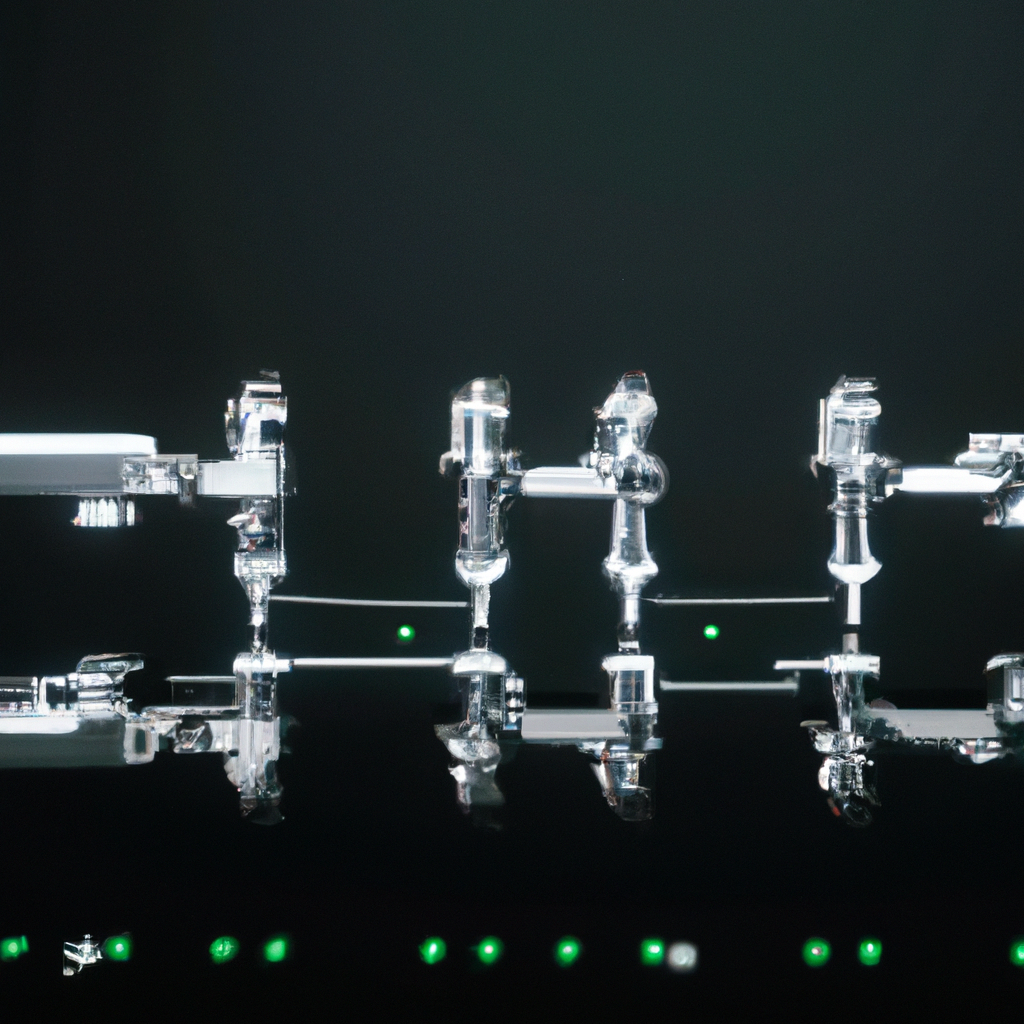

AI-powered predictive maintenance involves using machine learning algorithms to analyze data from equipment sensors, IoT devices, and other sources to identify potential equipment failures. Machine learning algorithms can analyze vast amounts of data to identify patterns and anomalies that indicate potential equipment failures. This analysis is done in real-time, allowing maintenance personnel to take action before the equipment fails.

Equipment Monitoring

AI-powered predictive maintenance relies on equipment monitoring. Equipment sensors and IoT devices are installed in critical equipment to monitor performance and detect potential failures. These sensors collect data on various parameters, such as temperature, pressure, vibration, and other factors, which are analyzed using machine learning algorithms to identify potential failures.

Data Analytics

Data analytics is an essential component of AI-powered predictive maintenance. Machine learning algorithms analyze vast amounts of data to identify patterns and anomalies that indicate potential equipment failures. This analysis is done in real-time, allowing maintenance personnel to take action before the equipment fails. Predictive maintenance algorithms can also use historical data to identify trends and predict potential failures in the future.

Maintenance Optimization

Maintenance optimization is another benefit of AI-powered predictive maintenance. By identifying potential equipment failures before they occur, maintenance personnel can plan and schedule maintenance activities when they are most convenient and cost-effective. This approach reduces downtime, increases equipment lifespan, and minimizes maintenance costs.

Smart Maintenance

Smart maintenance is an extension of predictive maintenance, where AI-powered algorithms are used to optimize maintenance activities. Smart maintenance involves using machine learning algorithms to analyze data from equipment sensors, IoT devices, and other sources to identify potential failures and optimize maintenance activities to reduce downtime, increase equipment lifespan, and minimize maintenance costs.

Impact on Industry 4.0

Industry 4.0 is the fourth industrial revolution, which is characterized by the integration of digital technologies into manufacturing processes. AI-powered predictive maintenance is one of the key technologies driving Industry 4.0. Predictive maintenance allows manufacturing companies to reduce downtime, increase equipment lifespan, and minimize maintenance costs, which is essential for maintaining competitiveness in the digital age.

Conclusion

In conclusion, AI-powered predictive maintenance is revolutionizing the maintenance industry. By using machine learning algorithms to analyze data from equipment sensors, IoT devices, and other sources, maintenance personnel can identify potential equipment failures before they occur, reducing downtime, increasing equipment lifespan, and minimizing maintenance costs. Predictive maintenance is an essential component of Industry 4.0, allowing manufacturing companies to stay competitive in the digital age. With the increasing adoption of IoT and machine learning technologies, we can expect to see more advanced predictive maintenance solutions in the coming years.