3D Printing: An In-Depth Look at the Additive Manufacturing Process

The world is experiencing a technological revolution, and 3D printing is at the forefront of this revolution. It is a process that has changed the way we think about manufacturing, design, and production. 3D printing is a form of additive manufacturing that has been around since the 1980s, but it has gained popularity in recent years due to its versatility and cost-effectiveness. In this article, we will take a closer look at 3D printing, how it works, its advantages and disadvantages, materials used, applications, and the future of this technology.

What is 3D Printing?

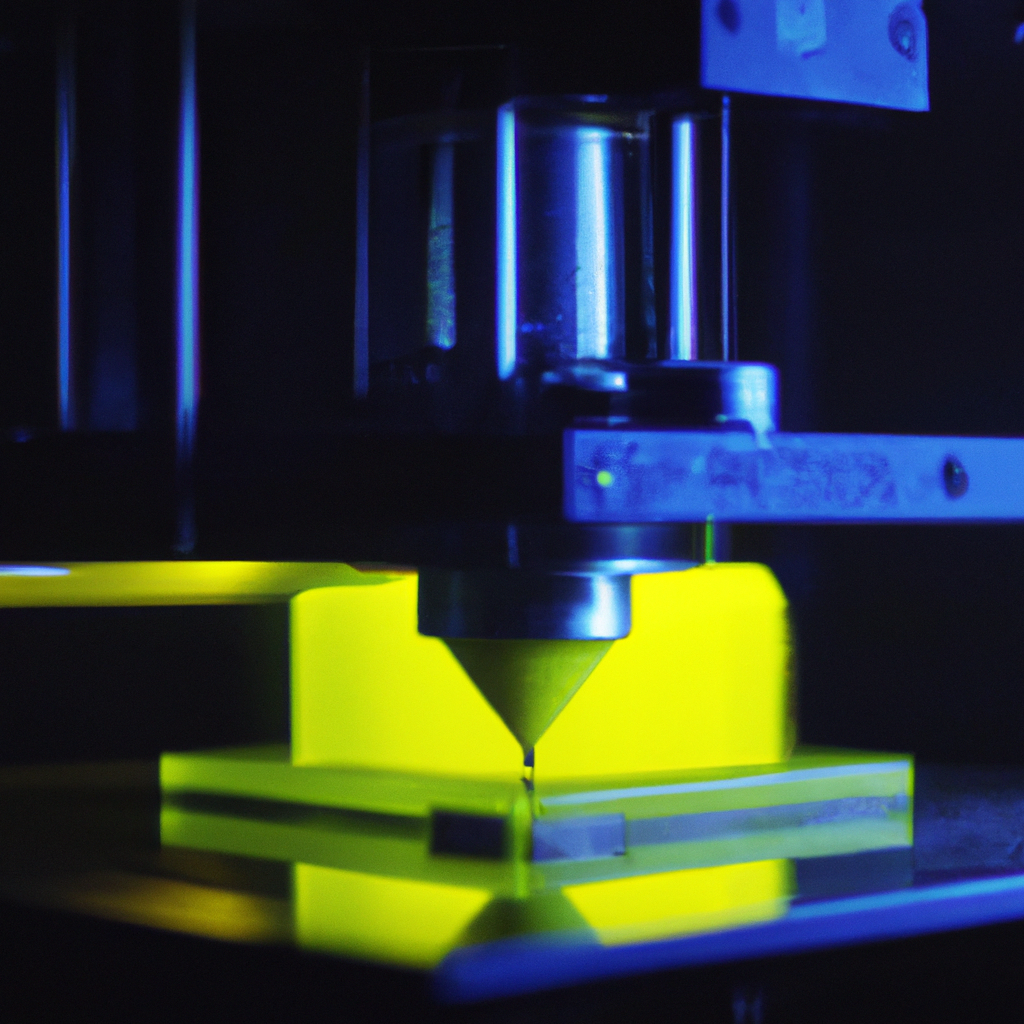

3D printing, also known as additive manufacturing, is a process of creating a three-dimensional object from a digital file. It is called additive because the process involves adding layers of material one by one until the final product is complete. The process is entirely different from traditional manufacturing processes, which involve subtracting from a block of material until the desired shape is achieved. 3D printing is a flexible process that allows for the creation of complex, intricate shapes that would be impossible to achieve with traditional manufacturing techniques.

How Does 3D Printing Work?

The 3D printing process involves several stages that work together to create the final product. These stages include:

1. Designing the 3D Model: The first step is to create a digital model of the object you want to print. This can be done using 3D modeling software or by scanning an existing object with a 3D scanner.

2. Slicing the Model: The next step is to slice the digital model into thin layers. This is done using slicing software that calculates the number of layers required to create the object and the thickness of each layer.

3. Preparing the Printer: Once the model is sliced, the printer must be prepared. This involves selecting the appropriate printing material and loading it into the printer.

4. Printing the Object: The final step is to print the object. The printer reads the sliced data and creates the object layer by layer. The printer head moves back and forth, depositing the printing material layer by layer until the object is complete.

What Materials Are Used in 3D Printing?

3D printing materials are diverse and depend on the type of printer being used. Some common materials include:

1. Plastics: PLA and ABS are the most common materials used for 3D printing. They are easy to use, inexpensive, and can be used in a wide range of applications.

2. Metals: Metals such as titanium, steel, and aluminum can also be 3D printed. These materials are commonly used in the aerospace and automotive industries.

3. Composites: Composites such as carbon fiber and glass fiber can be used to create strong, lightweight objects.

What Are the Advantages and Disadvantages of 3D Printing?

Advantages:

1. Cost-effective: 3D printing reduces the cost of production by eliminating the need for expensive tooling and molds.

2. Customization: 3D printing allows for the creation of customized products to fit the specific needs of the customer.

3. Rapid prototyping: 3D printing allows for the rapid creation of prototypes, reducing the time it takes to bring a product to market.

Disadvantages:

1. Limited materials: The range of materials that can be used in 3D printing is limited compared to traditional manufacturing processes.

2. Limited size: The size of the object that can be printed is limited by the size of the printer.

3. Quality issues: The quality of the final product may not be as high as that of traditionally manufactured products.

What Are Some Applications of 3D Printing?

3D printing has a wide range of applications, including:

1. Healthcare: 3D printing is used to create prosthetics, implants, and surgical tools.

2. Manufacturing: 3D printing is used to create parts for machinery, tools, and equipment.

3. Architecture: 3D printing is used to create architectural models and prototypes.

4. Fashion: 3D printing is used to create unique and intricate pieces of jewelry and clothing.

The Future of 3D Printing

The future of 3D printing is bright, and the technology is expected to continue to grow and evolve. Some future developments include:

1. Increased use in manufacturing: As the technology continues to improve, 3D printing is expected to become more commonly used in manufacturing.

2. Increased use of bioprinting: Bioprinting is a form of 3D printing that uses biological materials to create organs and tissues. This technology is expected to become more commonly used in the medical field.

3. Improved printing materials: The range of printing materials is expected to expand, allowing for the creation of more complex and intricate objects.

Conclusion

3D printing is a versatile and cost-effective manufacturing process that has the potential to revolutionize the way we think about design, production, and manufacturing. While the technology is still in its early stages, it is expected to continue to grow and evolve in the future. As the range of materials expands, and the technology continues to improve, 3D printing is expected to become more commonly used in a wide range of industries, from healthcare to architecture to fashion.