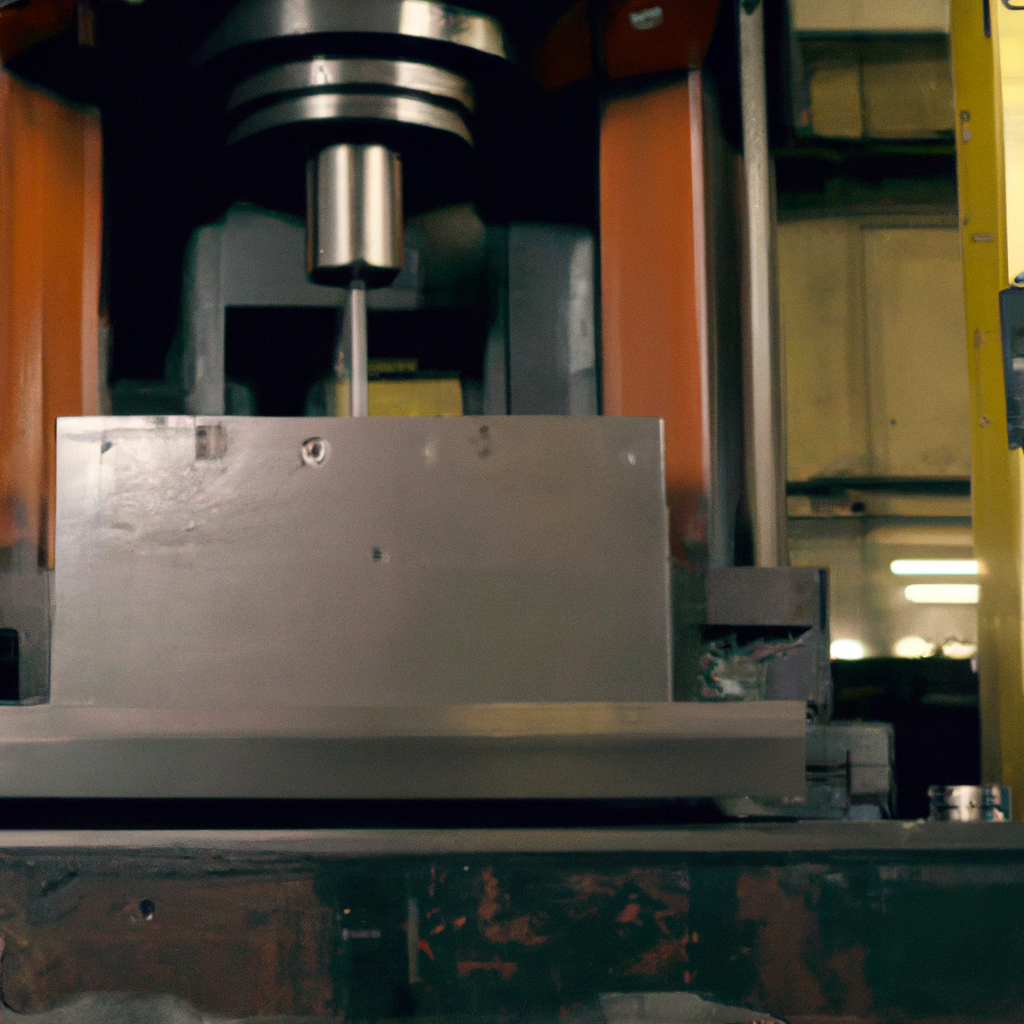

A hydraulic press is a machine that uses pressure to exert force on metal, plastic, or other materials. The machine is used in manufacturing, production, and metalworking to create a wide range of products. The hydraulic press works on the principle of Pascal’s law and is widely used in the industry due to its high force output, precision, and safety features. In this article, we will take a closer look at how a hydraulic press works.

Working principle

The working principle of a hydraulic press is based on Pascal’s law, which states that when pressure is applied to a confined fluid, the pressure is transmitted equally in all directions. The hydraulic press consists of two cylinders, one larger than the other. The smaller cylinder is known as the plunger, and the larger cylinder is the ram.

When hydraulic fluid is pumped into the smaller cylinder, it exerts pressure on the plunger, which then pushes the fluid into the larger cylinder. The fluid then fills the larger cylinder and pushes the ram upwards with a great deal of force. The force generated by the hydraulic press is determined by the area of the ram and the pressure exerted by the hydraulic fluid.

Pressure

The pressure exerted by the hydraulic press is determined by the amount of force applied to the plunger and the surface area of the plunger. The pressure is then transmitted equally in all directions, resulting in a force that is far greater than the force applied to the plunger. The hydraulic fluid used in the press is usually oil, which is incompressible and able to transmit the pressure effectively.

Force

The force generated by a hydraulic press is determined by the size of the ram and the pressure exerted by the hydraulic fluid. The larger the ram and the higher the pressure exerted by the fluid, the greater the force generated by the press. The force generated by a hydraulic press can be as high as several thousand tons, making it ideal for heavy-duty manufacturing and metalworking.

Mechanical engineering

Hydraulic presses are designed and built by mechanical engineers who specialize in manufacturing and production machinery. The design of the hydraulic press is crucial to its performance, safety, and reliability. The press must be able to withstand the high forces generated by the hydraulic fluid and the stresses generated by the manufacturing process.

Manufacturing

Hydraulic presses are widely used in manufacturing to produce a wide range of products. The press can be used to bend, shape, and cut metal, plastic, and other materials. Hydraulic presses are used in the automotive industry to produce car body parts, in the aerospace industry to produce airplane parts, and in the construction industry to produce building materials.

Production

Hydraulic presses are used in production to mass-produce products quickly and efficiently. The press can be programmed to perform a specific task repeatedly, ensuring consistent quality and reducing production time. Hydraulic presses are used in the food industry to produce juice, in the pharmaceutical industry to produce pills, and in the textile industry to produce clothing.

Machinery

Hydraulic presses are complex machines that require specialized knowledge and training to operate. The press must be maintained regularly to ensure its proper functioning and safety. The hydraulic fluid used in the press must be checked and replaced periodically to prevent contamination and degradation.

Metalworking

Hydraulic presses are widely used in metalworking to shape and cut metal. The press can be used to form metal into various shapes and sizes, including sheets, plates, and tubes. Hydraulic presses are used in the shipbuilding industry to produce ship parts, in the oil and gas industry to produce pipelines, and in the mining industry to produce mining equipment.

Industrial equipment

Hydraulic presses are essential industrial equipment that is used in various industries to produce a wide range of products. The press is widely used due to its high force output, precision, and safety features. The hydraulic press has revolutionized the manufacturing and production industry, making it possible to produce products quickly, efficiently, and cost-effectively.

Conclusion

In conclusion, a hydraulic press is a machine that works on the principle of Pascal’s law. The press uses hydraulic fluid to generate a force that is far greater than the force applied to the plunger. Hydraulic presses are widely used in manufacturing, production, and metalworking to produce a wide range of products. The press is designed and built by mechanical engineers who specialize in manufacturing and production machinery. The hydraulic press is an essential industrial equipment that has revolutionized the manufacturing and production industry.