Bronze metal clay is a popular material used in jewelry making, especially for creating artisan and handcrafted jewelry. The process involved in creating bronze metal clay jewelry requires a combination of metal clay techniques and metalwork. In this article, we will explore the steps involved in creating bronze metal clay jewelry, from the design stage to the finished product.

Designing the Jewelry

The first step in creating bronze metal clay jewelry is designing the piece. This is the stage where the jewelry designer decides on the style, size, and shape of the jewelry. The design can be hand-drawn or created using computer-aided design (CAD) software.

Creating a Mold

Once the jewelry design is finalized, the next step is to create a mold. The mold can be made using various materials such as silicone, rubber, or plaster. The mold is a replica of the design and is used to create the jewelry piece.

Preparing the Bronze Clay

Bronze clay is a combination of metal powder, organic binder, and water. The metal powder used is a mix of copper and tin. The organic binder helps to hold the metal powder together, and the water is used to create a workable clay-like material.

The bronze clay is prepared by mixing the metal powder, organic binder, and water. The mixture is then kneaded until it forms a smooth and uniform clay-like material. The clay is then left to rest for a few hours to allow the water to evaporate, making it easier to work with.

Creating the Jewelry Piece

Once the bronze clay is ready, the jewelry piece can be created. The mold is filled with the bronze clay, and any excess clay is removed using a scraper or knife. The clay is then left to dry for a few hours or overnight, depending on the size and thickness of the piece.

Firing the Jewelry

After the clay has dried, it is ready to be fired. Firing is the process of heating the clay to a high temperature to remove the organic binder and fuse the metal particles together. The firing temperature and time depend on the type of bronze clay used and the size of the jewelry piece.

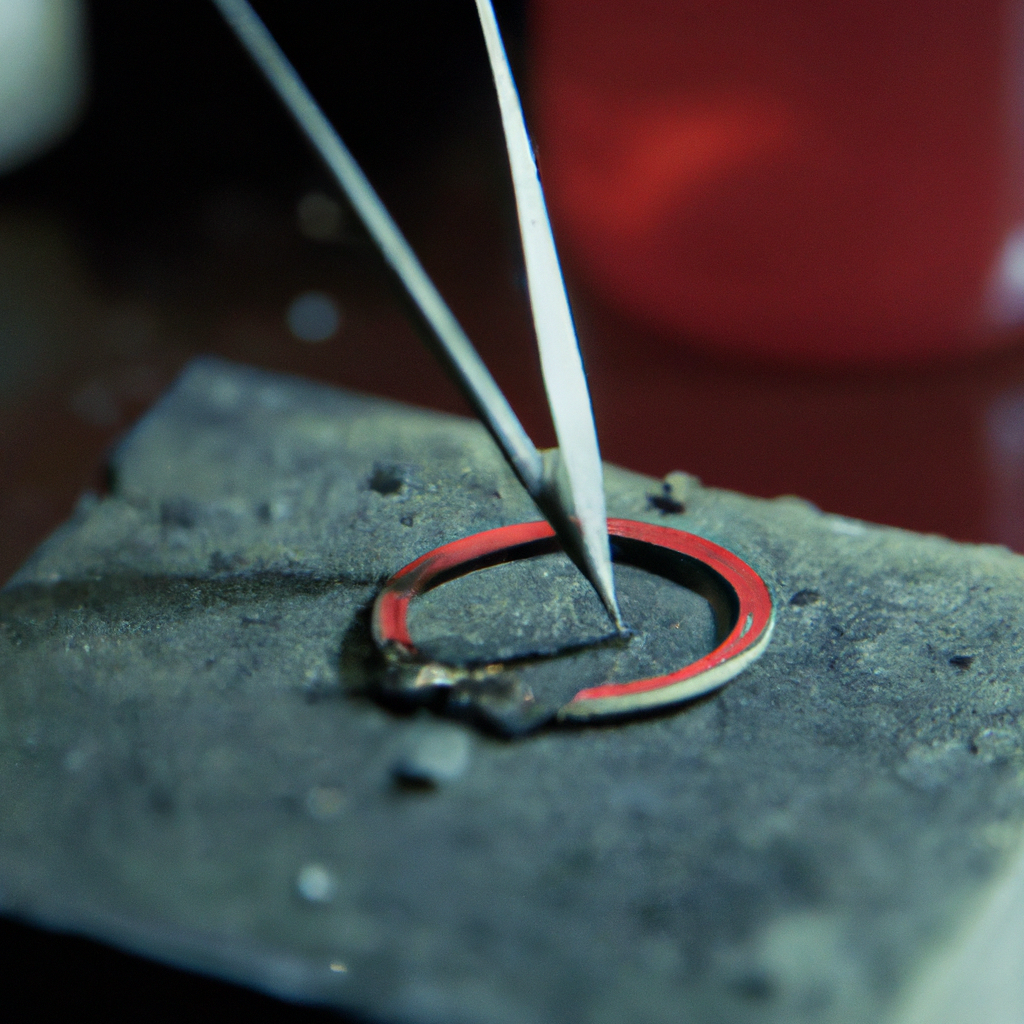

The firing process can be done in a kiln or with a torch. The jewelry piece is placed in the kiln or held with tweezers and heated with a torch until it reaches the required temperature. Once the firing is complete, the jewelry piece is left to cool.

Finishing the Jewelry

After the jewelry piece has cooled, it is ready to be finished. Finishing involves removing any rough edges or imperfections, polishing the piece, and adding any final touches such as a chain or clasp.

Bronze metal clay jewelry can be finished in various ways, depending on the desired style. Some finishing techniques include:

– Sanding: Sanding is used to remove any rough edges or imperfections from the jewelry piece. Sandpaper with different grits is used to achieve a smooth and even surface.

– Polishing: Polishing is used to give the jewelry piece a shiny and reflective surface. A polishing cloth or abrasive compound is used to achieve a high shine.

– Patina: Patina is a chemical process used to add color to the metal. A patina solution is applied to the jewelry piece, and the color is achieved through a reaction with the metal.

Conclusion

Creating bronze metal clay jewelry involves a combination of metal clay techniques and metalwork. The process begins with the design stage, followed by creating a mold, preparing the bronze clay, creating the jewelry piece, firing the piece, and finishing the piece. Bronze metal clay jewelry can be finished in various ways, depending on the desired style. With these steps, anyone can create beautiful and unique bronze metal clay jewelry pieces.